In today’s fast-moving, data-driven supply chains, unit serialization has become a foundational element for maintaining control, accuracy, and accountability. By assigning a unique identifier to every individual product unit, businesses can achieve real-time visibility across the lifecycle of an item, from manufacturing to distribution to the final point of sale. This level of precision is no longer just a best practice; in many regulated industries, it’s a requirement. Unit serialization empowers organizations to trace products instantly, manage inventory with greater accuracy, and respond quickly to quality or compliance issues such as recalls or diversion.

Beyond compliance and operational efficiency, unit serialization opens the door to smarter decision-making and enhanced customer trust. It helps businesses authenticate products, combat counterfeiting, and gain insights into product performance and movement. Whether you’re managing pharmaceuticals, electronics, or cannabis, serialization adds a layer of transparency and security that strengthens every link in the supply chain. In this post, we’ll explore why serialization is becoming essential infrastructure for modern inventory and supply chain management, what that means for cannabis businesses and how you can serialize units with Metrc Retail ID.

Today, many brands are applying QR codes selectively with the intent to either provide insights to consumers around product information or leveraging it as a scannable identifier for the product at point of sale. Each of these approaches serve their own purpose, but when handled independently of one another they miss the opportunity to streamline both of these objectives into a singular QR code, which is what Retail ID provides. Furthermore, if Retail ID unit serialization capabilities aren’t utilized, additional feature functionality to optimize inventory management of finished goods are missed throughout the supply chain.

Unit serialization defined

Unit serialization means assigning a unique identifier (ID) to every retail-ready sellable unit. Instead of applying one shared label to all containers of a specific product, each packaged unit receives its own code, allowing systems to track individual units rather than general categories.

A standard SKU might refer to a generic product, such as a 3.5 gram jar of Blue Dream. With unit serialization, that jar becomes distinguishable from every other 3.5 gram jar of the same strain. It now has a unique reference that can be used for tracing, authenticating, and managing its lifecycle.

Unit serialization turns each product into its own identifiable item, which can be followed from manufacturing through distribution and final sale. This is the foundation for full traceability and compliance. Without unit serialization, operational visibility remains limited, and critical functions like authentication, returns, and audit trails could suffer.

What is Retail ID and how does it create unit level serialization?

Retail ID offers a seamless approach to managing product labeling through serialized QR codes, directly connecting each finished product to essential information such as strain, cannabinoid and terpene profiles, batch number, testing results, Certificate of Analysis (COA) and production history. This solution was created to support efficient traceability, compliance, and transparency across the supply chain.

Although brands are printing QR codes, some may only associate it with a package ID from Metrc, missing out on the transparency benefits offered to consumers with Retail ID. Other brands who do print the Retail ID may only print one QR and apply it to the entire batch, missing out on the opportunities to establish proof of purchase with their customer base or have a more robust approach into their inventory management practices.

Why serialization matters for brands

Implementing unit-level serialization supports a number of business functions that impact both internal operations and external relationships. These include:

- Traceability

Uniquely serialized identifiers make it possible to track each individual product more clearly through the supply chain. This supports internal quality control and provides visibility into product movement—laying the foundation for understanding sell-thru performance by unit, store, or market. - Sell-thru rate optimization

Sell-thru rate—the percentage of units sold compared to units supplied—is a vital performance metric for brands and retailers alike. Serialization unlocks this insight at the unit level, helping brands evaluate product performance, optimize distribution, and drive smarter production decisions. - Authenticity verification

Unique codes help prevent counterfeit products by allowing retailers and consumers to confirm origin and legitimacy. This trust boosts consumer confidence and encourages faster purchasing decisions, helping to improve sell-thru rates. - Inventory accuracy

Serialized labels allow businesses to manage inventory with precision, reducing discrepancies, shrinkage, and dead stock. Better inventory management leads to the right product being in the right place at the right time—key for maximizing sell-thru. - Recall efficiency

In the event of a recall, serialization allows brands to isolate and withdraw only the affected units, avoiding disruption to unaffected products. This reduces cost (labor, time, and product) and inventory confusion. Plus, consumers and business partners are more likely to trust a company that can execute targeted and transparent recalls. - Customer support

Serialization simplifies warranty processing, return management, and consumer inquiries by linking specific products to their production history. A smoother post-sale experience supports brand loyalty and re-purchase, which fuels higher sell-thru over time. - Regulatory readiness

As traceability requirements evolve, brands and retailers leveraging unit serialization will be better positioned to meet evolving expectations, reducing interruptions in sales and ensuring continued product availability.

How to get started with unit serialization

For teams ready to adopt serialization, the following steps can provide a reliable starting point:

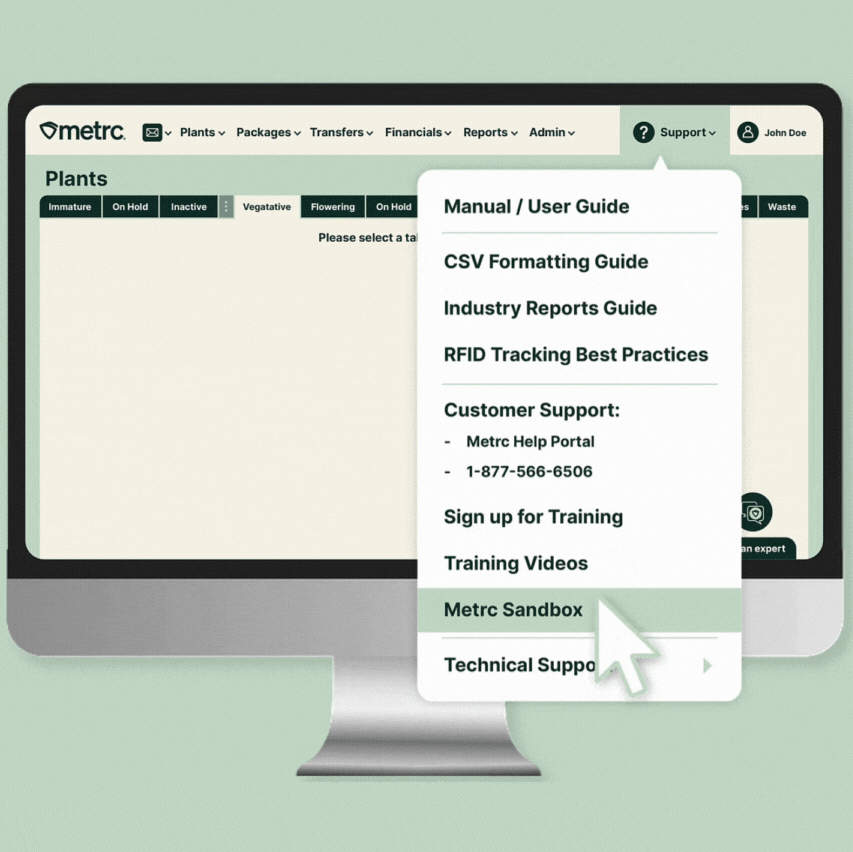

- Review labeling software and hardware

Confirm that your current tools can generate and print uniquely serialized QR codes at the unit level. Older versions of Zebra Designer or non-specialized platforms may not offer this capability. - Download through Metrc

If you’re in a state where Retail ID is enabled, you can download serialized QR codes or even Finished Good Labels directly through the Metrc system. - Use structured CSV uploads

Create serialized identifiers in bulk using CSV upload templates. This method supports efficient scale without requiring manual creation of each label. - Need help?

Licensed Metrc users can reach out to Metrc Support via our support portal, by phone at 877-566-6506, or via live chat.

The broader impact

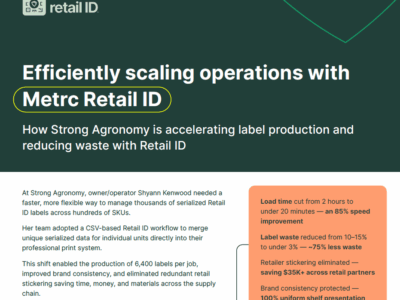

Brands that are leveraging full unit serialization report improvements across multiple operational areas. With serialization in place:

- Scan and receive becomes functional

- Case-level tracking is accurate

- Packaging and returns can be validated with confidence

Retailers are also better equipped to process inventory quickly, identify discrepancies, and support consumers. Full serialization unlocks visibility into sell-thru at the unit level—enabling brands to track how products perform across locations, optimize inventory decisions, and respond to demand with precision. The result is a more transparent, reliable, and data-rich system from end to end.

What’s next

Labeling is a starting point. Unit serialization transforms that label into a functional tool that supports accuracy, trust, and retail readiness. It enables full scale traceability, allows systems to operate with more precision, and supports relationships throughout the cannabis supply chain.

The data is clear. Brands that fail to implement unit serialization miss out on opportunities to improve how their products move, how their inventory is managed, and how their partnerships function.

This is not a small adjustment. It is a key business decision that impacts every part of the product lifecycle.

To begin implementing unit serialization or to learn more about Retail ID workflows, contact your Metrc representative or visit our knowledge center. Every product you label is a chance to deliver more clarity, more confidence, and better outcomes.