When a perfect code still will not scan

Metrc Retail ID labels used in cannabis retail stores work only when the QR code prints cleanly enough to scan correctly. That scan is a pivotal moment for accuracy, efficiency, and transparency, whether it’s a cannabis retailer moving product through intake, a regulator auditing cannabis inventory, or a consumer pulling up product details. If the printed QR code is fuzzy, the workflow stalls.

This comes up more often than people expect. One operator, Zachary Giachetti of Oregonix Farm in Illinois, experienced this challenge firsthand: the QR codes looked fine on screen, but scanners struggled after printing from a PDF. The issue was not the code. It was the print output.

That’s what this post is about: QR code print quality. The mechanical reality of getting a Metrc Retail ID QR code onto a cannabis label so it scans every time.

Why print quality matters for cannabis Retail ID workflows

Retail ID is built around unit-level identification for cannabis products via a QR code placed on a label – or, more simply put, a way to track and manage cannabis items through the supply chain using a unique identifier on each unit.

When print output is low quality, the effects show up immediately:

- Slower workflows at receiving, intake, or checkout because scanners need multiple attempts

- More reprints, more manual checks, more label handling

- More friction with cannabis retail partners, because they feel the delay first

- A lost consumer moment. If the QR code is meant to support cannabis transparency, a failed scan is a dead end

Serialized labels only create efficiency when the physical and digital product data match. A failed scan interrupts that flow and quickly becomes added labor, reprints, and extra steps.

DPI and why it changes QR code print quality

DPI means dots per inch, or the resolution your printer uses to render lines and edges. With Retail ID QR codes, DPI detail matters because scanners depend on crisp separation between dark and light modules. When resolution is low or when print settings blur edges, the modules can visually merge, and the scanner sees noise instead of a recognizable pattern. Lower DPIs can combine sections of the code, and the goal is to force that separation for quality and usability.

Real-world testing results speak for themselves:

- Printing with a 1200 DPI printer straight from the PDF works cleanly

- Lower-resolution printers struggled without adjustments

To experience efficiency and quality results, cannabis operators don’t necessarily need to buy the highest-end printer available. The takeaway is that cannabis QR code print quality depends on resolution and proper settings. Lower DPI hardware can work, but it often requires more careful setup.

QR code size rules that matter in cannabis packaging

Metrc’s Retail ID Resource Center lists two standard QR code sizes for cannabis labels and a limit that should not be crossed:

- Small: 0.5″ x 0.5″

- Large: 0.75″ x 0.75″

- Not recommended below 0.35″ due to scan impact

This is where cannabis teams often get tripped up. To make room for branding or compliance text, the QR code size gets deprioritized. Sometimes it happens accidentally when a label template is resized. On a lower DPI print, that small Retail ID QR code can turn into a dense cluster that scanners struggle to read.

A simple rule helps: if you are printing smaller codes, you are asking more of your printer and its settings. Keeping Retail ID QR codes at one of Metrc’s standard sizes reduces the risk of scan failures.

Troubleshooting QR codes that will not scan

Start with the basics, then move into the settings that tend to cause trouble when incorporating Retail ID QR codes during cannabis label printing.

1) Confirm the printer is using its highest resolution mode

If your printer supports multiple modes, set it to the highest available resolution.

- Higher resolution produces cleaner edges

- Cleaner edges improve scanner recognition

If you must use lower-resolution printing hardware:

- Increase QR code size

- Keep contrast high and backgrounds clean

2) Look for graphics settings that soften edges

Many printers apply smoothing or dithering – a technique to fake smoother detail by adding a little bit of controlled “noise” – to make images look better. For Retail ID QR codes, that can be harmful because these settings alter the pattern the scanner expects.

For example, if you’re using a Zebra printer, which is commonly used in cannabis, these printers include a properties setting which should be set to the most detailed option available.

If the Retail ID QR code on your cannabis label output looks speckled, softened, or is slightly rounded at the edges, this is often a sign that graphics handling is interfering with the code.

3) Increase overall QR code size, not just height

A common cannabis labeling mistake is adjusting only one dimension. A few quick tips:

- Changing the height alone does not improve scans and stretching the height can impact scannability

- Increasing the overall size gives scanners more usable data

A simple test helps:

- Print one QR code on a label at a smaller than standard size

- Print one QR code on a label at a standard, recommended Metrc size

- Print one larger QR code on a label where the height is stretched

Then, scan each of the QR codes with the same device to gauge ease of readability and see what issues may occur.

4) Print side-by-side comparisons

Troubleshooting works best when it is controlled:

- Same QR code

- Same label stock

- Same scanner

- Only one change per test print

Comparing a QR code printed directly from the PDF with one enlarged to fill more of the tag space often shows why size matters.

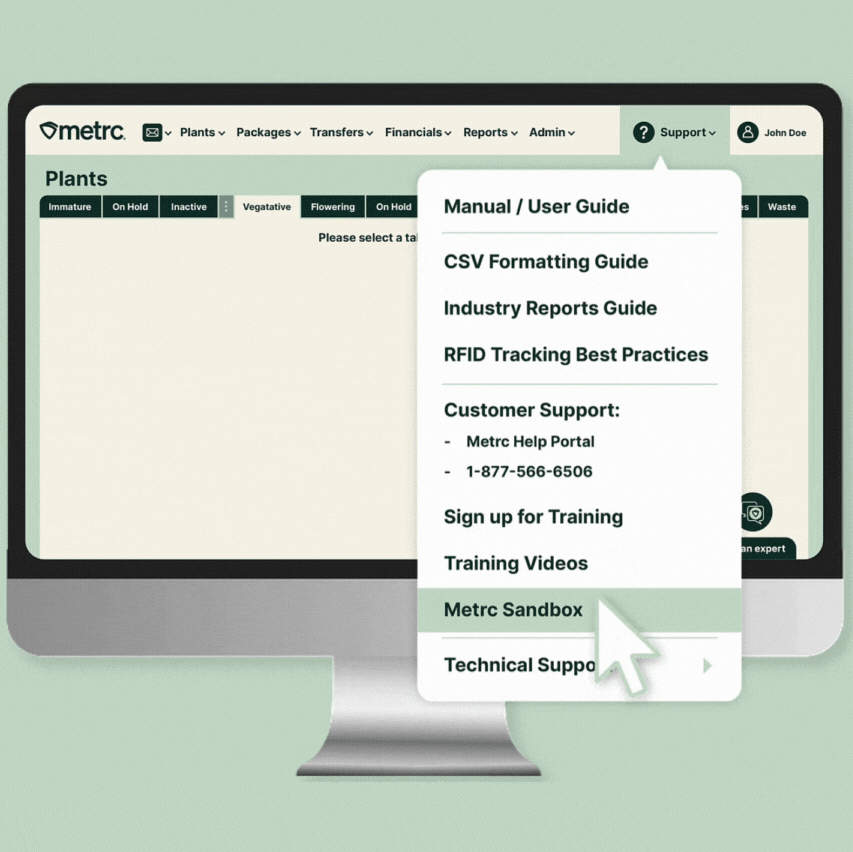

5) Verify the Metrc label generation workflow

Metrc workflows allow QR codes to be created and downloaded as PDFs for printing. If scans fail, confirm that:

- You are printing the native PDF output

- The QR code was not copied, pasted, or rasterized – meaning it was turned into tiny dots (pixels) so a computer or screen can display it

- The file was not resaved in a way that degraded resolution

Once you download your Retail ID QR codes as a PDF, open the file in Adobe Acrobat to print. Tip: Print directly from the Acrobat application, not from the web browser preview.

Here are the recommended scanners that have performed best based on Metrc testing:

- Zebra H-6672 (2D, wired only) – Wired is preferred for POS to avoid misplaced or mixed-up scanners. Purchase on Amazon.

- Zebra DS2208 – Reliable; personally tested for over 6 years with excellent performance. Purchase on Amazon.

- Zebra DS2278 – Very similar to the DS2208; wireless option with proven reliability. Purchase on Amazon.

- Zebra CS6080 – High-performance 2D scanner. Purchase on Amazon.

- Zebra CR6080 – Durable and versatile 2D scanner.

When CSV workflows cause QR code degradation in printing software like NiceLabel or Bartender

Teams using CSV workflows with label design software, like BarTender or NiceLabel, can accidentally degrade Retail ID QR code quality.

How labeling software’s handle CSV files of QR codes

Like many labeling softwares, BarTender and NiceLabel treat QR codes as objects on a label, just like text boxes or images. Those objects have properties that control size (width/height), module size (the tiny squares that form a QR code), scale or fit-to-box behavior, print quality or rendering mode.

When users import CSV data the software regenerates the QR code from the data, rather than preserving the native PDF’s original rendering. That’s not inherently bad, but it means the label software’s object settings now control resolution, sizing, and edge handling, not Metrc’s original output.

Common failure points when using a CSV file for Retail ID

When CSV data is imported and the QR object is regenerated by the software instead of using the native PDF output, the following problems appear:

- The QR resolution defaults to a lower DPI than the printer

- Scaling rules may shrink the code below 0.35″ without warning

- Anti-aliasing – to soften module edges by blending pixels together – can be applied by default (which is great for photos and graphics but not for QR codes)

- Template lock-in can reuse outdated sizing or module settings

The most common failure: A QR code that looks correct in the software preview but prints with softened edges because the code is being rasterized instead of preserved in vector form.

In practice, fixing it comes down to keeping the QR object at a consistent size, turning off smoothing, and running a quick test print to ensure clean edges and dependable scans.

Best practices that prevent scan failures before they start

These habits protect print quality and save cannabis teams time and frustration.

A quick print check before you ship labels

Before a full print run:

- Print five labels

- Scan them with a 2D Barcode scanner and a mobile device

- Reprint with higher detail or larger QR codes if scans struggle

- Repeat until scans are fast and reliable

Treat QR code print quality as a production control step, not a packaging detail.

Key takeaways

- QR code print quality drives speed and reliability in Retail ID workflows.

- Higher DPI helps, but printer settings still matter.

- Print and test a small set before mass printing. Scan with retail scanners, warehouse scanners, and phones if applicable.

- Native outputs and stable print workflows reduce errors. Print from the PDF output using stable settings. Preserve the original QR code quality and avoid workflows that downsample graphics.

- Use standard Metrc QR code sizes and avoid shrinking below 0.35″.

- Use labeling software guides when needed. Specialized tools reduce accidental QR degradation.

- Troubleshoot one variable at a time. Printer drivers or firmware changes often cause subtle issues. Contact your hardware provider’s support if needed.

Your labels impact how your product shows up in the real world

A Retail ID QR code on cannabis packaging and labels is more than an add-on or nice-to-have. It is a functional part of a product’s identity. When a code scans cleanly, operations feel smooth. When it does not, everyone assumes something is wrong.

The irony is that the QR code is one of the most objective parts of the label. It either scans or it doesn’t. And the fix is usually small:

- A DPI setting

- A print mode

- A sizing choice made months earlier

That dependable, no-surprises scan is the goal. When labels stop drawing attention and just work, workflows are simplified, retail partners take notice, and product data transparency functions the way it should.

Frequently Asked Questions

Q: Why will my Retail ID QR code not scan even though it looks fine on screen?

A: Retail ID QR code scan failures in cannabis packaging usually stem from print quality issues like low resolution, softened edges, or codes printed too small. Increasing size and using the highest detail print setting often fixes the problem.

Q: What QR code sizes does Metrc recommend for cannabis Retail ID labels?

A: Metrc lists two standard sizes: 0.5″ x 0.5″ and 0.75″ x 0.75″. Reducing below 0.35″ increases the risk of scan failure.

Q: Can lower DPI printers work for cannabis QR codes?

A: Lower DPI printers can work if QR codes are larger and print settings maximize detail. Test scans in small sets before full production.

Q: Do I need special software to print Retail ID labels?

A: Some cannabis teams print directly from PDFs, while others use labeling software. Dedicated tools provide more control but are not always required. For more information on recommended hardware and software, check out this resource.

Q: What should I change first when scanners struggle at retail?

A: For retailers, start by confirming the scanner is configured properly and is 2D-capable. Once that’s in place, brands should focus on print settings—use the correct resolution mode, increase QR code size, and disable graphics smoothing.

Q: Is QR code height adjustment useful?

A: Increasing overall QR code size is more effective than adjusting height alone.

Q: Can PDF printing affect scan reliability?

A: Yes. PDF settings can resize or blur the QR code, especially if the software downscales or applies smoothing. To avoid this, open the PDF in Adobe Acrobat (not a browser), print at 100% scale, and ensure high resolution and no graphics smoothing. This keeps the QR code sharp and consistent for scanners.

Q: Why do phone cameras scan but retail scanners fail?

A: Phone cameras have powerful image processing that can compensate for small or blurry QR codes. Retail scanners are less forgiving—they rely on clear, high-contrast printing and proper sizing. So a code that works on a phone may still fail on a fixed scanner if it’s too small, low-resolution, or smoothed.