Radio frequency identification (RFID) technology is central to Metrc’s industry-leading track-and-trace solution, but what is RFID exactly, and what makes it so effective, especially in the cannabis market? This revolutionary technology is a comprehensive tool used globally across industries and businesses to gain efficiencies in traceability, supply chain management, and much more.

RFID: The Basics

RFID as we understand it today was first patented in the early 1980s, though its origins stretch back even further. Ever since, it has flourished into a technology that’s revolutionized business and changed how we think about supply chains.

It comes in many different forms, but it boils down to one simple concept: tags are used to create a one-of-a-kind digital identifier that companies, regulators, and others can use to track objects as they move through the supply chain.

How does it work? RFID readers use radio frequency waves, or RF, to identify a tag containing a small microchip that acts as an object’s digital passport, receiving a virtual stamp whenever it’s scanned. The possibilities for RFID are limitless, and it is used in commercial and industrial applications as varied as accounting for checked bags on a flight, providing accurate product inventory while reducing waste to enhance quality and efficiency in food delivery, and even securely processing credit card payments in lieu of a magnetic strip or embedded chip. And unlike a barcode, an RFID tag doesn’t need to be within the reader’s line of sight, so it can be embedded in the tracked object.

Some of the most common forms of RFID are ultra-high frequency (UHF), high frequency (HF), near-field communication (NFC), and low frequency (LF). RFID tags can also be passive (which means they don’t need an additional power source like a battery) or active. Each has its own advantages, and at Metrc we use UHF RFID. This means inventory managers can read their tags from a longer distance and in larger quantities – a critical feature when inventory totals can stretch well into the hundreds and beyond.

With consumer expectations continuing to rise, businesses need technology that streamlines logistics and increases productivity. This is where RFID comes in.

RFID Across Sectors

RFID technology is already transforming more than just cannabis, from automobiles to restaurants, fresh produce, and major retailers. For example, Kia utilizes RFID tags by attaching them to automobiles during production, tracking its progress through the assembly line. Chipotle Mexican Grill is piloting RFID technology to help the company trace ingredients that move through its distribution center and to approximately 200 Chicago-area restaurants, helping capture and manage data regarding supplies, as well as ensure food safety and operational efficiency at each site.

Australia’s Bartle Frere Bananas is piloting RFID technology to track batches of fruit as it’s harvested and shipped to customers, while Internet of Things (IoT) sensors track moisture and nitrates to protect the Great Barrier Reef. Additionally, Walmart began utilizing RFID technology to track apparel and merchandise back in 2019, a successful effort leading to a recent expansion in RFID tracking to consumer electronics and kitchen appliances.

Unmatched Advantages with RFID

RFID is transformative technology with numerous advantages over traditional barcodes.

Scanning More Items, More Quickly

First, it decreases time spent tracking product inventory while providing more accurate inventory data. And because RFID doesn’t require line-of-sight access to scan tagged objects, RFID tagged products can be tracked without having to be physically scanned, eliminating the need to turn the object over if the barcode isn’t visible, for example.

Multiple RFID tags can also be read remotely and simultaneously, and at vastly increased distances – meaning a warehouse worker could wave an RFID equipped scanner through a row of shelves containing hundreds of RFID tagged products and obtain an accurate inventory count in seconds.

Reducing Room for Error

In addition to RFID’s time-saving benefits, it yields more accurate inventory counts by mitigating human error. This is because each asset or tagged item is detected and identified automatically, and it is matched up with the correct information in a product database using its unique ID. It eliminates the possibility of human errors in scanning, logging, or updating information on paper records or in a spreadsheet. This allows manufacturers to maintain a completely accurate inventory of all tagged assets and properly account for current assets and future supply chain, planning, or equipment needs.

Reducing Costs, Increasing Durability

Moreover, RFID technology is saving businesses money by reducing capital costs. An effective way to keep costs low is to maintain tight control of assets, especially expensive business assets like test equipment, transport packing, computer tech, field vehicles, and more. If any of these suddenly disappear, replacing them could cost a business dearly. In addition to expensive assets, the loss or improper tracking of a large quantity of products may cost a business hundreds or thousands of dollars in compliance fines. RFID tags are also much more durable than barcodes through its ability to withstand exposure to harsh temperatures and certain chemicals. Simply put, RFID provides an easy and inexpensive way to keep track of assets.

To see these benefits in action, look no further than the U.S. Patent and Trademark Office (USPTO), which adopted RFID to track more than 100,000 IT assets. In under three years, USPTO reported more than $1 million in annual savings, a 54% reduction in error costs, and more than 11,000 saved labor hours each year.

RFID & Cannabis: The Perfect Match

The regulatory maze of the cannabis industry is complex and compounded by each state’s unique laws governing its own cannabis industry. This has made cannabis an industry in serious need of an efficient and sensible way to comply with changing regulations across a range of jurisdictions. Moreover, cannabis growers must document nearly everything they do during daily operations. Depending on the number of plants in a greenhouse or packages in a warehouse, it may take hours or days for employees to manually record the data on each plant and package. Although taking visual stock can be a big help, relying on manual data collection can produce expensive errors. With such a complex environment and so many varying needs, RFID is a natural fit.

The Benefits of RFID in Cannabis Industry: The Metrc Difference

The RFID system we use allows for reading several tags at the same time, including those that are hidden from sight, helping to decrease human error and increase labor efficiency. In a cannabis cultivation facility with thousands of plants to tag and track, the benefits are clear.

RFID saves more than just time for cannabis cultivators. Because the cannabis industry is so tightly regulated, a discrepancy between internal and government reported inventory could result in hefty penalties for the manufacturer. RFID systems offer automated data collection, so it is easier to stay on top of inventory in real-time and remain compliant with government regulations.

This technology also provides item-level tracking of individual cannabis plants, with real-time reporting back to the respective regulatory body. Properly implemented RFID tags withstand the unique environments of indoor and outdoor cannabis cultivation facilities. And in the scenario that a specific plant or group of plants need to be located inside of a large warehouse surrounded by thousands of identical plants, RFID tags provide Real-Time Locating Services (RTLS), enabling manufacturers to quickly locate individual plants.

This isn’t just limited to plants in the warehouse, either. RFID track-and-trace technology like the solution Metrc deploys allows both industry and regulators to identify products at any stage in the supply chain and, if necessary, stop it before it reaches end consumers.

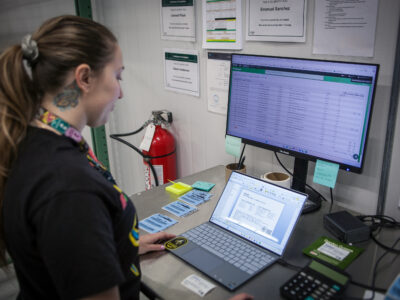

For licensed cannabis businesses, the benefits of our state-of-the-art RFID technology we deploy in states throughout the country is best realized through third-party integrators who offer RFID readers to regulators.

Bringing RFID to Your Business

RFID is changing the way businesses operate around the globe. Want to learn more about how RFID integrates with the Metrc system? Check out more on The RFID Difference and how the Anatomy of an RFID Tag offers unique benefits to the cannabis industry.